Waste materials become raw materials and valuable resources

Carbonauten’s proprietary carbonization technology is characterized by flexibility in input and output, process controllability, energy efficiency and robustness. These are decisive criteria for low production costs, specific product properties, high qualities and quantities. In a “minus CO2 factory”, production can be adapted to material flows, special product requirements or changing markets within just a few hours. The unique process also makes it possible to carbonize or recarbonize (= convert back into carbon) input with impurities such as stones, minerals, soils, metals and plastics.

Saw residues

Nothing remains

In wooden construction, the whole tree cannot be used for building. NET Materials® change that: residual wood from sawing is turned into biocarbon and then into CO2-storing half-finished products for pipes, films, profiles, insulation, concrete, plaster and more.

Wood chips

A classic

Wood chips are available in large quantities on a global scale and are an excellent source material for technical biocarbons.

Nutshells, etc.

The perfect ecosystem

Farmers supply us with biomass and we supply them with electricity, heat and agricultural NET materials regardless of location, which in turn increase yields. This way, organic farming becomes more efficient, effective and profitable – Which makes healthy food cheap for everyone.

Bamboo, Miscantus

CO2 absorbing devices

Bamboo grows up to one meter every day. On average, one hectare of bamboo stock absorbs about 17 tons of CO2 per year. The high carbon density makes it particularly hard, making it an excellent construction material as well as a starting material for NET Materials®.

Screen overflow

From being problematic material to being an enrichment for communities

In the laboratory, together with MVV Umwelt, we were able to prove that screen overflows can be carbonized. Screen overflows occur during the final screening of compost in waste management. They contain tree branches, plastics, metals, bones and other impurities.

Waste wood A1-A4

Old wood for new products

Class A1 and A2 waste wood often contains screws, nails, plastics and other impurities. When shredded, they are carbonized on the basis of the 4th Federal Immission Control Act and refined into NET Materials®. With the 17th Federal Immission Control Act, the processing of contaminated waste wood A3 and A4 is possible.

Root trunks

A problem becomes an efficient fertilizer

Rootstocks that are costly and time-consuming to dispose of, are simply shredded together with soil and stones and then carbonized. The result is mineralized biocarbon and sanitized soil, in other words, excellent materials for agriculture and forestry.

Problem materials

Back to carbon

So-called recarbonization enables the transformation of problematic waste materials into valuable materials. Non-recyclable fiber composites, residues containing plastics and paper sludges were successfully carbonized in the laboratory.

… and many more

Characteristics of the directly heated batch retort process

Pyrolytic carbonization processes, as continuously operating processes (rotary kilns, piles), usually require precisely pre-processed and small-sized input materials that can only be processed at a defined and high process temperature. This makes biocarbons expensive, limits their uses, and keeps quantities low. Impurities such as metals, plastics and stones have to be sorted out in advance, as they lead to wear and malfunctions. In addition, the biocoals are usually extinguished with water to prevent self-ignition, which results in a water content of 20-40%, and increases their sales weight. Because of this, biocoals are not offered by weight, but by volume.

The minus CO2 factories of carbonauten are designed for the carbonization of various woody residues and problem materials. For this purpose, a unique, directly heated batch retort process has been developed, which is wear-free and fail-safe. The static slow pyrolysis does not contain any moving parts, as anything that is in motion is also subject to malfunctions. This also allows materials with interfering substances such as metals, stones, plastics and resistant fibers to be carbonized. In addition, each individual batch is digitally traceable. Defined, gas-based cooling produces technical biocarbons with 0% water content, which form the basis for high-quality carbonauten NET Materials®.

Characteristics

- Direct heating of biomass residues

- Modularly expandable and movable

- Can be used for a wide range of biomasses

- Wear-free and robust (no moving parts)

- High product quality

- Precise temperature control between 400° – 700° Celcius

- Continuous operation 24/7, at least 8,000 hours/year

- Excellent energy balance (1 MWth waste heat/module)

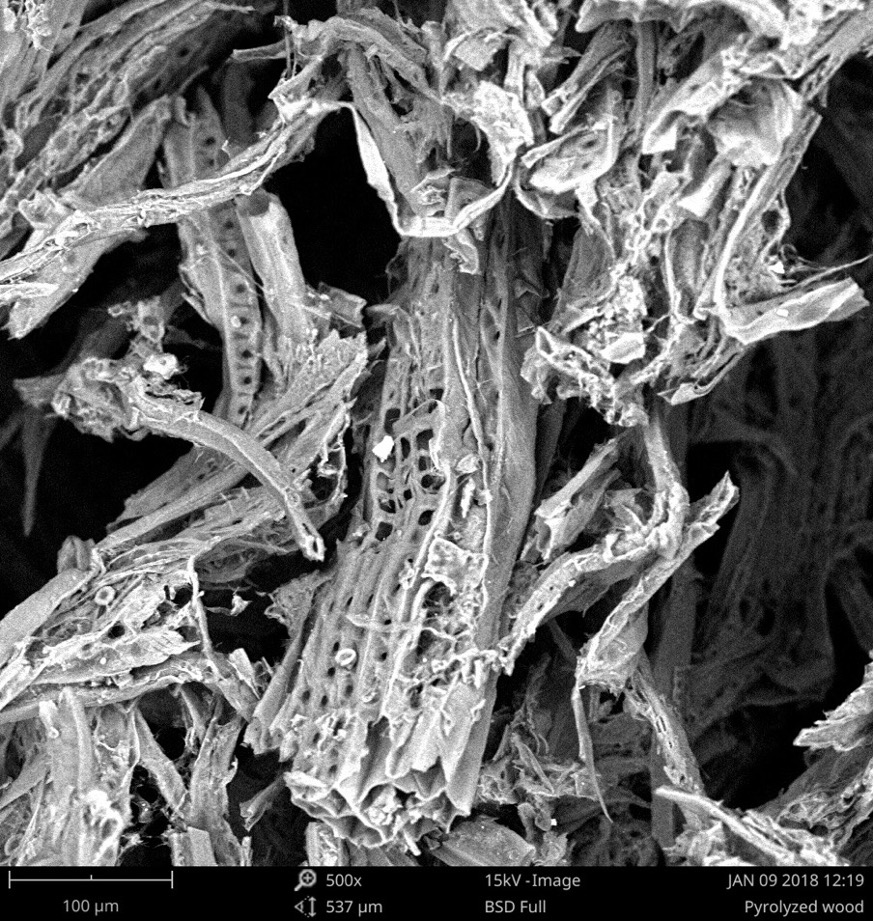

Super material carbon

Carbon C is the fourth most abundant element in the universe and is on position 14 in the periodic table of elements. It is the basic precondition for all organic life. It is most likely that carbon came to our planet only during the primeval cooling phase via meteorites and asteroids. Humans consist of carbon by more than one-fourth. Fossil resources such as petroleum, coal and natural gas are the remains of primeval biomasses compressed under pressure and heat.

Technical biocarbons are multi-talented, they…

- bind and store CO2

- have surface areas of 100 to over 2,000 m2 per gram (SEM image on the right)

- are very lightweight with an atomic mass of 12.011.

- bind 3 – 6 times their own volume in water

- have adjustable surface properties and polarities

- conduct or prevent the flow of electrons

- absorb and bind substances harmful to the environment

- are resistant to environmental influences and UV exposure

- resist heat up to several hundred degrees Celsius

- cause hardening, dimensional and pressure stability

- create black as natural product color / replace Carbon Black

Recent

CO2-negative parts for the ICE

For the first time, seat shells and armrests of the ICE were injection molded from CO2-negative plastic with a biocarbon content of 33%....

Construction of minus CO2 factory 002 begins in Chibi, China

On 7 November 2023, carbonauten GmbH started construction of the world's largest carbonisation plant for the extraction and storage of CO2...

What characterizes a carbonaut? (2/2)

Continuation of the previous blog post. We keep talking. About money, politics and vision. Aaron: You mentioned funding issues earlier. In...