carbonauten polymers

CO2-negative, technical biocarbon composites

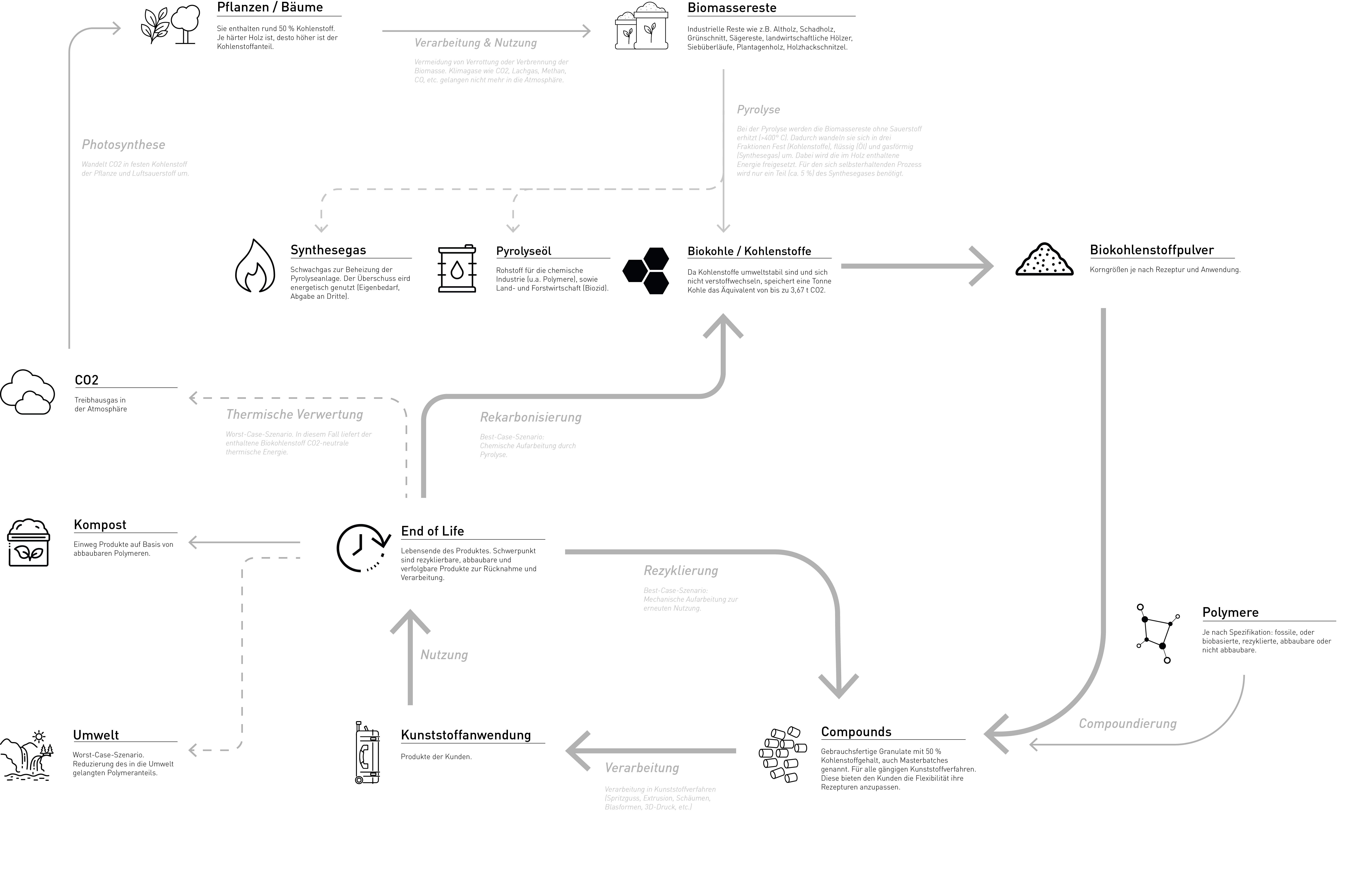

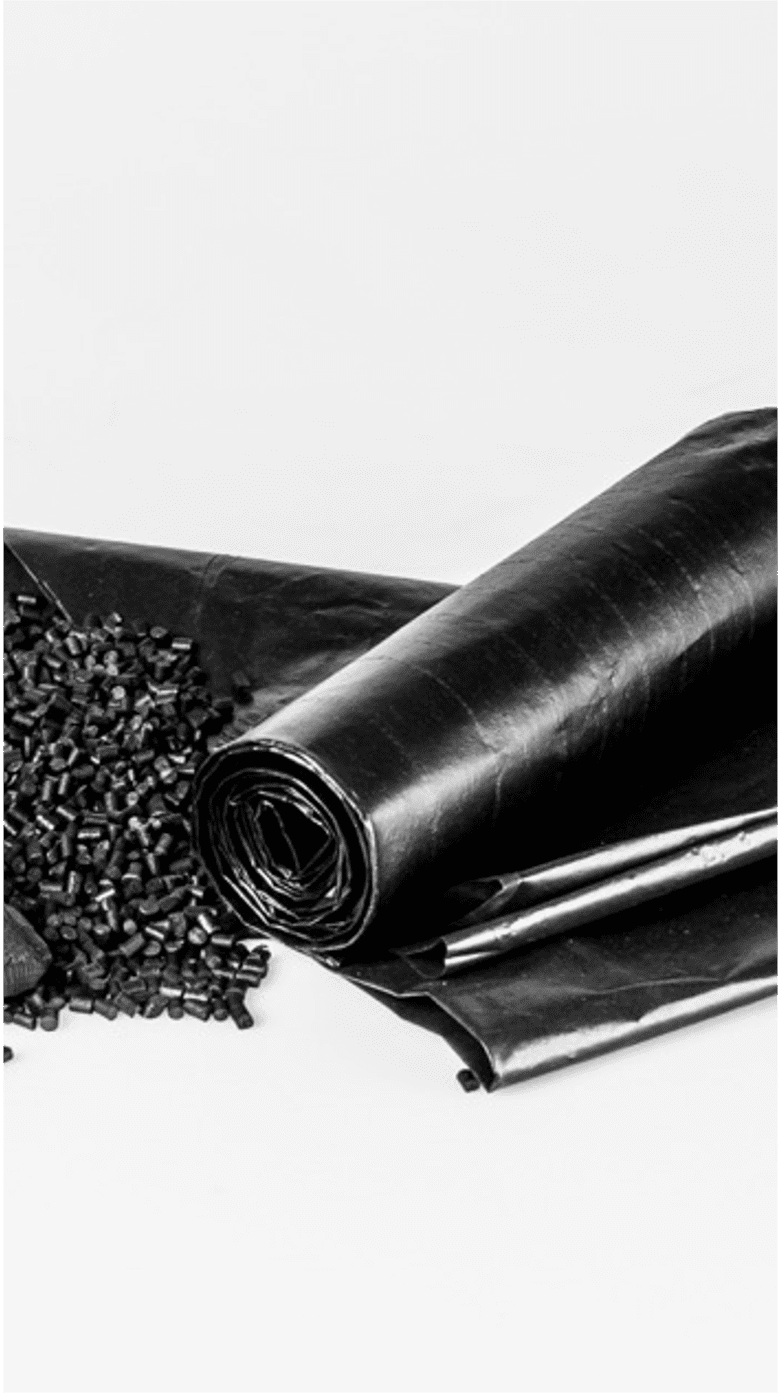

carbonauten polymers develops and produces ready-to-use, CO2-negative compounds and masterbatches. Many properties of the plastics are improved, costs are reduced and recyclability is retained. The granulates are processed in the same way as other plastics. In addition to standardized composites, customer-specific granulates are also possible.

Plastics become a CO2 sink

By enriching the compounds with up to 50% biocarbon, carbonauten polymers plays an important role in reducing CO2 emissions and transforming the plastics industry. The long-term goal is to achieve fill levels of 90% technical biocarbon.

carbonauten Tech BioC Composites

carbonauten®

ABS Tech BioC 40/70/5 IM

- ABS composite with 40% biocarbon

- Increased stiffness, thermal stability and dimensional stability

- Natural black surface aesthetics

carbonauten®

HP Tech BioC 50/70/0.3 ET

- 50% biocarbon developed for thermoforming and extrusion applications.

- The parts produced are characterized by a balanced ratio of stiffness and impact strength (tests at room temperature) in combination with a reduced CO2 footprint

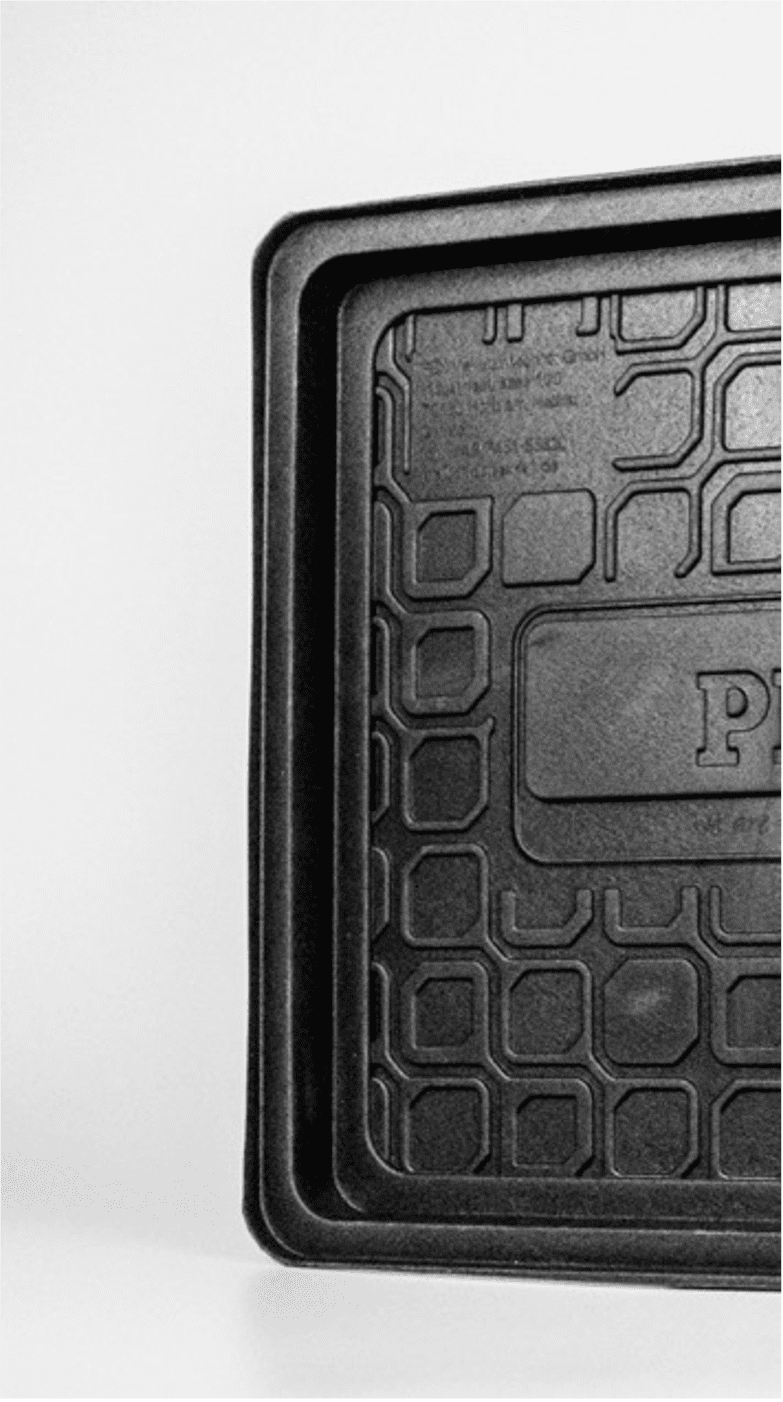

carbonauten®

ICP Tech BioC 50/70/4 IM

- Polypropylene copolymer with 50% biocarbon

- Impact resistant, excellent stiffness, high thermal stability and dimensional stability

- Natural black surface aesthetics

carbonauten®

ICP Tech BioC 50/70/6 IM

- Polypropylene with 50% biocarbon

- Excellent stiffness, high thermal stability and dimensional stability

- Natural black surface aesthetics

Properties of carbonauten NET Materials® as masterbatches and compounds

1

Biodegradable or stable (depending on the polymer)

Recarbonizable

Recyclable

2

Low prices

3

High temperature and UV resistance

4

Improved dimensional stability

5

High stiffness

6

Reduced weight

7

Organic material from biomass residues

8

Natural, non-toxic black colour

9

Effective absorption of odors in recycled polymers

High stiffness

10

measurable CO2-reduction

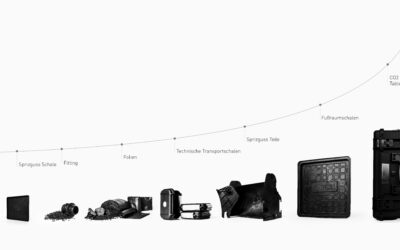

carbonauten NET Materials® – proof of concept

Hardware-Cases

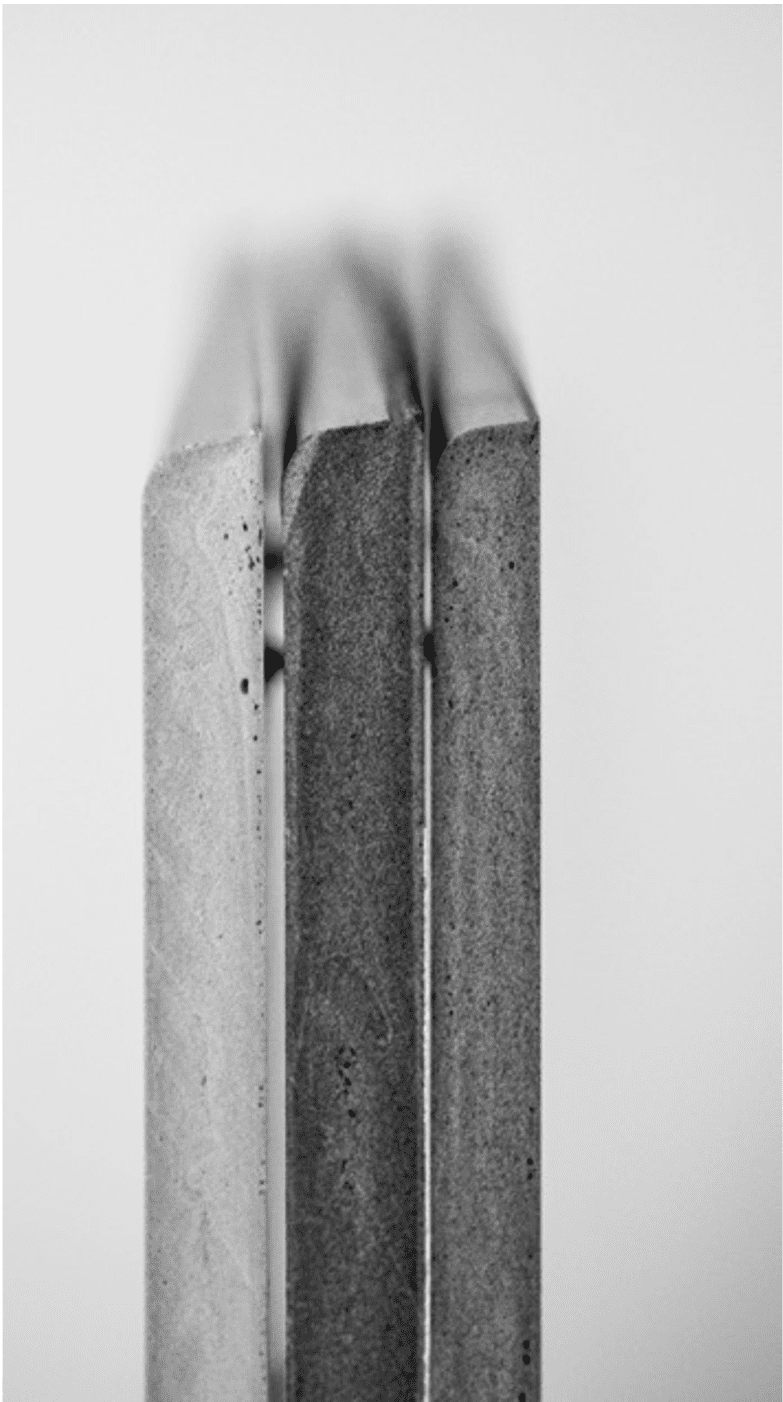

Foams

Extruded parts

Injection molded parts

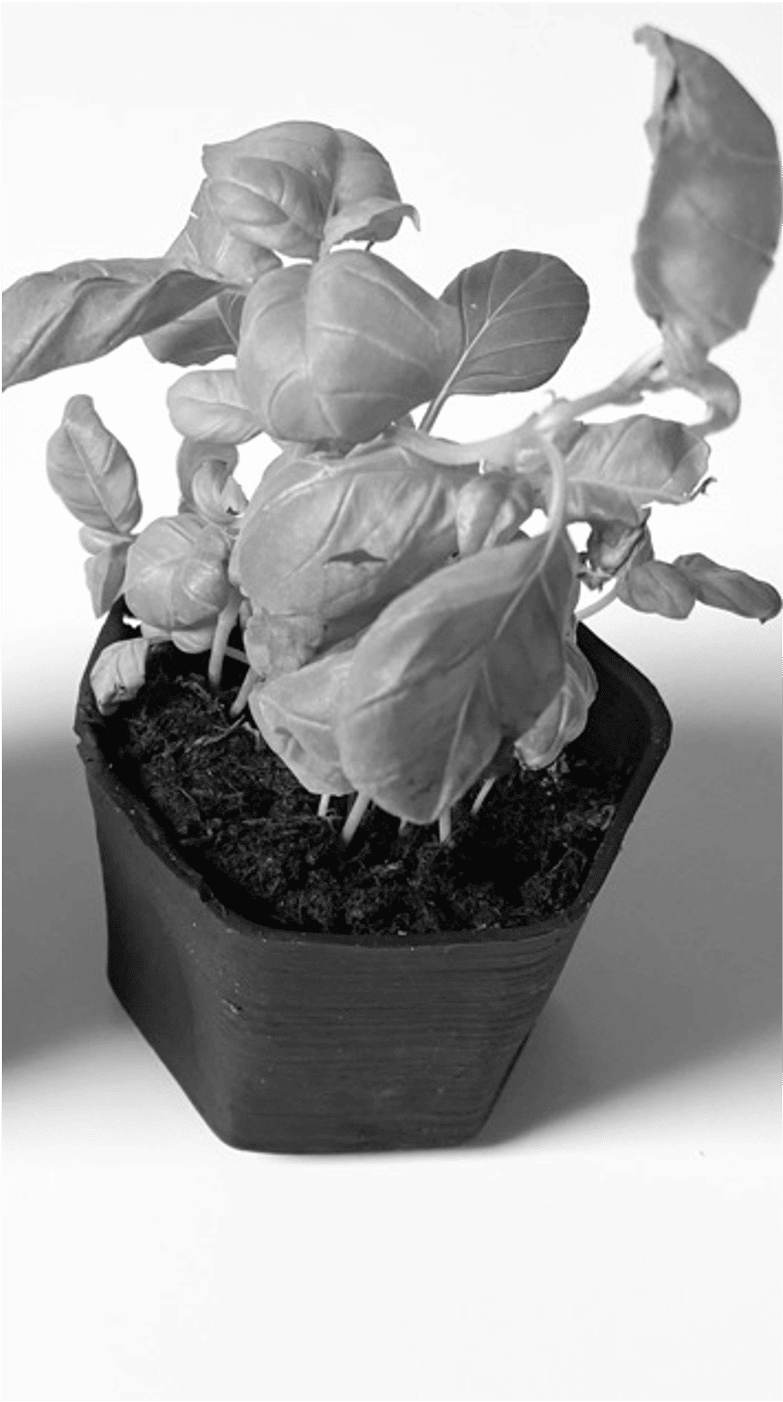

Degradable plant pots

Testing rods

Insulation panels

Piping and fittings

Films

Deep drawn parts

Latest from polymers

Climate turnaround: A high-tech case stores CO2

How a regenerative future is created from waste materials The time has come: Introducing the first ready-to-use minus CO2 product by...