The maximum cascading and recirculating use of resources

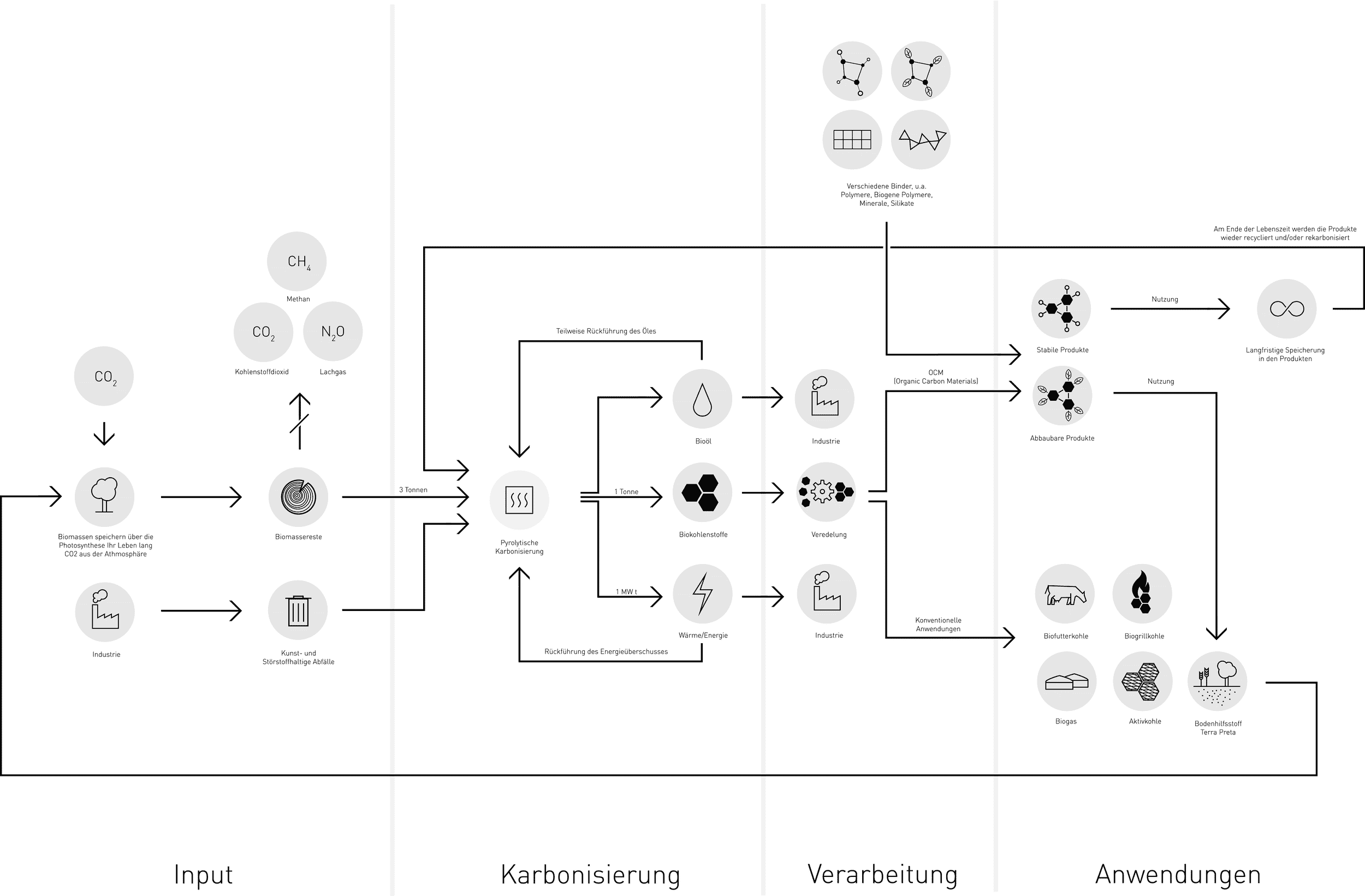

The complete carbonauten system, including all participants and nature, goes far beyond the production of technical biocarbons. It reverses the CO2 spiral, materializing the previously gaseous carbon from the air and storing it temporarily or permanently in objects and soils, depending on the application. This is achieved through the use of carbonauten NET Materials® in agriculture, forestry and the construction industry. Other applications temporarily store excess amounts of carbons in a recirculating system, such as in plastics. Recarbonization at the end of product life closes the cycle.

Dual scalability for rapid growth

In order to be able to reduce climate gases in the range of gigatons by 2030, the carbonauten system will be scaled up rapidly.

Decentralized, modular minus CO2 factories

Instead of complex and expensive large-scale plants, many decentralized minus CO2 factories will be built worldwide. This helps protect regional resources, and suitable biomass residues from within a radius of up to 70 km are carbonized where they are created. Local energy supply of companies, cities and communities is also a benefit. This creates sustainable and self-sufficient ecosystems.

Modular factory design

The carbonization technology of carbonauten is based on standardized production modules combined with conventional technical periphery. This enables the rapid realization of minus CO2 factories of various sizes tailored to local needs, as well as subsequent adaptations and expansions.

→ carbonauten offers companies and communities individually scalable, cost-effective energy generation with the use of CO2-negative and regenerative products and without capital investment.

Latest developments on sustainability and regeneration

Case study in Ghana

carbonauten conducted research in cooperation with a community of farmers from around Apam, Ghana and the German Society for International...

Products of carbonauten agriculture to strengthen the plant’s natural defenses

Markus Bayer is a farmer from Dischingen in East Württemberg. He grows corn and operates his own biogas plant. Many farmers are fighting...

Climate turnaround: A high-tech case stores CO2

How a regenerative future is created from waste materials The time has come: Introducing the first ready-to-use minus CO2 product by...